MOXIE (Mars Oxygen ISRU Experiment)

mission specific

Instrument Overview

The primary goals of MOXIE are to verify and validate Mars ISRU technology, and to enable potential future ISRU plants at the scale required for a human Mars mission. MOXIE produces oxygen from the carbon dioxide in Mars’ atmosphere using Solid Oxide Electrolysis (SOXE). MOXIE aims to produce at least 6 g/hr of oxygen, of at least 98% purity, on at least 10 separate occasions.

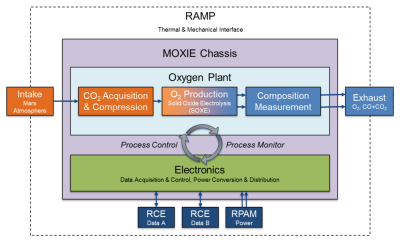

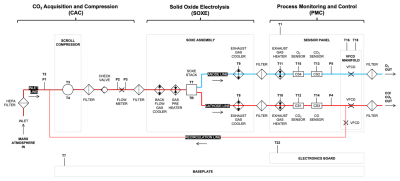

A block diagram of MOXIE is shown in the first figure below, and the major component parts are drawn in the second figure below. MOXIE is comprised of three major subsystems: the Carbon dioxide Acquisition and Compression (CAC) subsystem, the SOXE subsystem and the Process Monitoring and Control (PMC) subsystem. These subsystems are described in the following sections.

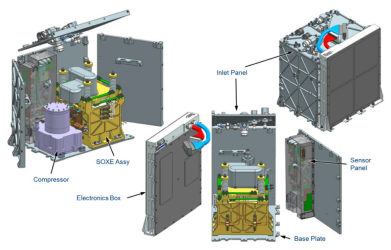

Exploded (left, center) and assembled (right) view of MOXIE, excluding components mounted externally on the rover chassis. The MOXIE enclosure has dimensions of 24 x 24 x 31 cm. The major component parts are the scroll compressor (shown in light purple), SOXE assembly (shown in gold), electronics box, base plate, inlet panel and sensor panel.

Carbon dioxide Acquisition and Compression (CAC) subsystem

The primary function of the CAC subsystem is to acquire and compress carbon dioxide from the atmosphere of Mars.

The atmosphere is drawn in and compressed to approximately 0.5 bar by a scroll compressor (Air Square, Inc., Broomfield, CO) operating at up to 3500 RPM. Downstream of the scroll compressor, a check valve is used to damp out pressure oscillations, a pair of pressure sensors on either side of an orifice is used to give an indication of flow rate, and a backflow gas cooler is used to prevent hot gases from damaging the check valve and backflowing in to the compressor during shutdown.

Because Mars' atmosphere contains dust, the atmosphere is filtered before it enters the scroll compressor. A High-Efficiency Particulate Air (HEPA) filter is used.

Solid Oxide Electrolysis (SOXE) subsystem

The primary function of the SOXE subsystem is to produce oxygen be electrolysis of carbon dioxide. Carbon monoxide is produced as a byproduct.

After exiting the backflow gas cooler, a heat exchanger heats the gas to approximately 800 °C. Conversion of carbon dioxide to oxygen is achieved using a SOXE "stack" (OxEon Energy, LLC, North Salt Lack, UT; formerly Ceramatec, Inc. Salt Lake City, UT). The SOXE stack is mechanically configured as a stack of ten electrolytic cells, and electrically configured as top and bottom half-stacks of five cells each. Each electrolytic cell consists of a stabilized zirconia electrolyte located between porous nickel composite electrodes. The cells are separated by interconnects. One side of each interconnect directs the inlet gas across each cathode, carrying carbon monoxide, unreacted carbon dioxide, and residual atmospheric gases to the cathode exhaust. The other side of each interconnect directs the pure oxygen product away from each anode to the anode exhaust. Heat exchangers recover the heat from the outlet gases.

As carbon dioxide is a mildly oxidizing gas, long-term operation can result in oxidation of the nickel catalyst in the cathodes. To prevent this, a few percent of the gas in the cathode exhaust is recirculated back to the scroll compressor inlet, so that the gas entering the SOXE stack contains a few percent carbon monoxide.

Process Monitoring and Control (PMC) subsystem

The primary functions of the PMC subsystem are to control the SOXE inlet mass flow rate, by either a compressor RPM or SOXE cathode pressure setpoint; the SOXE half-stack temperatures, by top and bottom heater temperature setpoints; the SOXE half-stack oxygen mass production rates, by top and bottom SOXE half-stack current setpoints; and to monitor MOXIE by recording data from MOXIE’s sensors.

Most sensors and flow control devices are collected on a sensor panel mounted behind the scroll compressor and SOXE assembly. Exhaust gas heaters are vestigial from an earlier design that maintained full temperature control of the sensors. An electronics box is mounted on the side. The locations of MOXIE’s pressure, temperature and gas composition sensors are shown in the figure below.